How Long Does Commercial Playground Equipment Last?

As much as we wish for commercial playground equipment to be around for a long time for children to enjoy, nothing truly lasts forever. The best playground equipment typically lasts 8 to 20 years, depending on maintenance, material quality, usage, and several external factors that affect its durability.

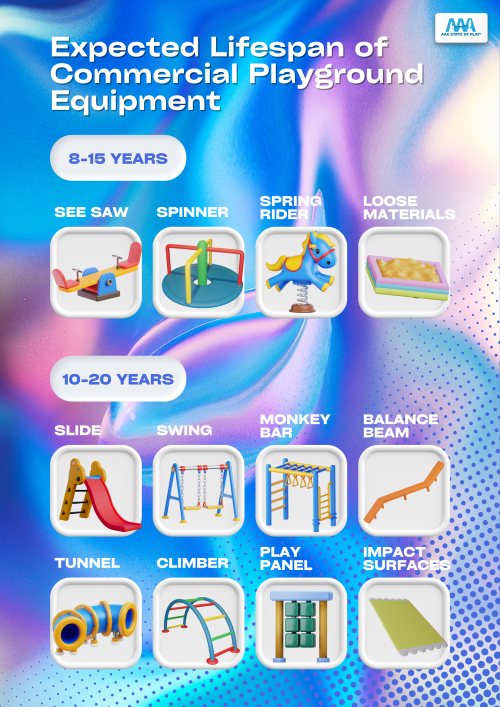

Expected Lifespan of Commercial Playground Equipment

The expected commercial playground equipment lifespan is generally 8 to 20 years, with some high-quality equipment lasting over 25 years. Several factors contribute to the longevity of commercial playground equipment:

- Materials used: Wooden playground equipment can last from 8 to 15 years. Plastic and rubber components can last from 10 to 15 years, while composite and metal structures can last up to 20 years.

- Construction quality: Outdoor play equipment made from high-quality materials and installed properly is guaranteed to have a longer lifespan.

- Frequency of use: High-traffic areas, such as school playgrounds, can greatly decrease the playground equipment lifespan compared to lower-traffic areas.

- Environmental conditions: Harsh weather, humidity, and sun exposure can affect the duration and durability of the equipment.

- Maintenance conditions: Periodic inspections and proper maintenance are important for increasing equipment longevity and eradicating safety hazards.

Another key detail affecting the equipment's longevity is the manufacturer's provided warranty. Warranties are closely related to the playground equipment lifespan as they reflect the manufacturer's confidence in product durability and provide the expected duration of use under normal conditions.

Maintenance Practices to Prolong Equipment Life

Maintenance is essential for prolonging lifespan of play equipment. Here are some important practices to help extend the durability of the equipment:

Regular Inspection

Even the best playground equipment, known for its high durability and longevity, is still susceptible to signs of wear and tear with regular use. Regular inspections for outdoor equipment are crucial for checking current conditions, identifying potential hazards, and preventing possible injuries. The inspection should cover moving parts, structure, hardware, and surfaces. Keep a detailed record of maintenance logs for reference and to track frequent issues.

Annual inspections by Certified Playground Safety Inspectors (CPSIs) should also be scheduled to maintain safety standards, double-check some details that might be missed during regular inspections, and address complex issues requiring professional expertise.

Cleaning and Lubrication

Regular equipment cleaning preserves hygiene and removes potential debris, grime, and pollutants. This is particularly important for high-traffic play areas, such as neighborhood parks and school playgrounds. Each type of playground equipment requires different cleaning methods, but mild soap, water, and disinfectants usually do the trick.

Aside from cleaning, lubrication is also applied to reduce friction, rust, and wear. It is often used on swing joints, bearings, and other mechanical components for smoother operation, especially for old playground equipment.

Tightening and Replacing Hardware

Hardware refers to components like screws, bolts, and nuts used in assembling and securing playground equipment. These components play a crucial role in the durability and safety of playground equipment. It is important to tighten them during regular inspections and replace them as needed to prevent accidents and potential risks.

Painting and Coating

Applying paints and coatings helps increase playground equipment lifespan, especially against rust, weather, and corrosion. This is particularly applicable to metal and wooden components that require extra protection and serve as additional playground safety measures.

Surfacing Maintenance

Commercial playgrounds are never complete without impact-absorbing materials, such as engineered wood fiber, artificial grass, and rubber surfaces. They keep a public play space, such as a community park or a school playground, safe by cushioning falls and preventing injuries from play. Ensure these surfaces are well-maintained by mending or replacing rubber tiles and refilling loose-fill materials like wood chips and sand as needed to avoid becoming a tripping hazard.

Addressing Environmental Factors

The environment can also greatly affect the durability and usage of the playground equipment. Apply coatings and preventive measures to increase the adaptability of the playground structures, such as anti-corrosion treatment for humid or coastal areas. Consider adding shades and covers for harsh weather and UV ray protection and prepare equipment for varying weather conditions.

Understanding Wear and Tear on Commercial Play Structures

Wear and tear are inevitable and can happen even to the best playground equipment. Recognizing these signs helps increase the lifespan and ensure safety and continuous enjoyment.

Signs of Wear and Tear

Visible and Invisible Indicators

Obvious signs like cracks, broken parts, and dents require immediate attention to preserve safety and continuous use, especially among commonly used playground equipment. Durability issues can also arise with hidden and overlooked wear such as internal rusting of pipe or tube structures and weakening of load-bearing amenities.

Structure Issues

The playground equipment's structure is a fundamental indicator of its current capacity and condition. Wobbling, instability, and unevenness can signal severe wearing or foundational issues. Loose or missing metal hardware can also compromise safety and require immediate replacements.

Functional Problems

Excessive smoothness and patchiness are common in frequently used equipment, such as swing seats, slides, and rubber safety surfaces. Although seemingly harmless, it is important to replace playground equipment or address them as needed for users' safety. Stiff and noisy playground structures like swings, see-saws, and spring riders may require lubrication or a general check-up to identify additional issues.

Factors Contributing to Wear and Tear

Material Used

Rotting and splinters are common among wooden playground equipment. Metal amenities and hardware are prone to rust and corrosion. Fading and discoloration can be signs of brittleness among plastic and composite equipment.

Usage Patterns

Busy parks and school playgrounds often experience high traffic, making their playground equipment susceptible to weakening compared to other locations. Crowd favorites like swing sets, slides, and climbing playground structures are often the first to show signs of wear in contrast to other equipment. Vandalism and misuse of equipment can also decrease the longevity of even brand-new playground equipment.

Environmental Factors

Weather conditions can affect the equipment differently and compromise playground safety depending on the material type. Excessive sun exposure can make plastic and composite equipment brittle. Rain and humidity can cause the rotting of wooden amenities and rusting among metal components and equipment. Extreme temperatures can also cause the expansion or contracting of materials, leading to cracking and unevenness.

Addressing Wear and Tear Issues

Daily Inspections

The frequency and thoroughness of inspections can make a difference in spotting early signs of wear and tear. Regular checking should be made following the harshness of the environment and the usage patterns within the area. A Certified Playground Safety Inspector (CPSI) should also be consulted at least annually for complex and overlooked issues.

Preventive Measures

No matter how high-end the best playground equipment claims to be, the lack of preventive measures will inevitably cut their lifespan short. Regular maintenance also extends the playground equipment's lifespan by eliminating possible risks and slowing down further weakening through coatings and treatment. Installation of shades and protective surfacing also increases protection from external factors.

Direct Actions

Once these signs of wear and tear on the playground equipment have been identified, address them immediately with appropriate measures. This helps prioritize safety by reducing the risks of injuries and accidents that might escalate if left unattended. Make sure that visible signs receive prompt solutions, while hidden issues are given additional procedures to address them effectively.

Every type of commercial playground equipment plays a crucial role in providing fun in shared playing spaces. Implementing these measures ensures no amenity is left out for the children and users' continuous benefit and enjoyment. No matter which outdoor playground equipment you choose today, AAA State of Play guarantees you a lifetime of fun experiences in all commercial spaces.

Learn about the author: Nic Breedlove